Autodesk Fusion for round design

CAD software program like Autodesk Fusion is an more and more very important device for firms getting into the fashionable period of design, the place ideas like circularity and cautious materials choice are indispensable for achievement. With over 80% of product-related environmental impacts decided within the design part (in keeping with the European Fee), leveraging the sustainable improvement instruments in Autodesk 3D modeling software program empowers companies to succeed twice: they’re able to give their tasks a sustainable edge available in the market whereas additionally contributing to a extra sustainable and accountable future.

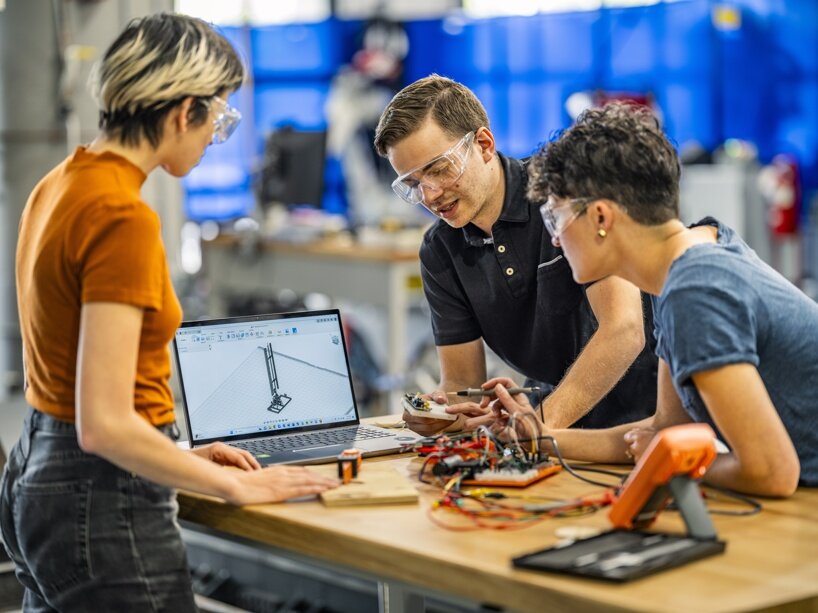

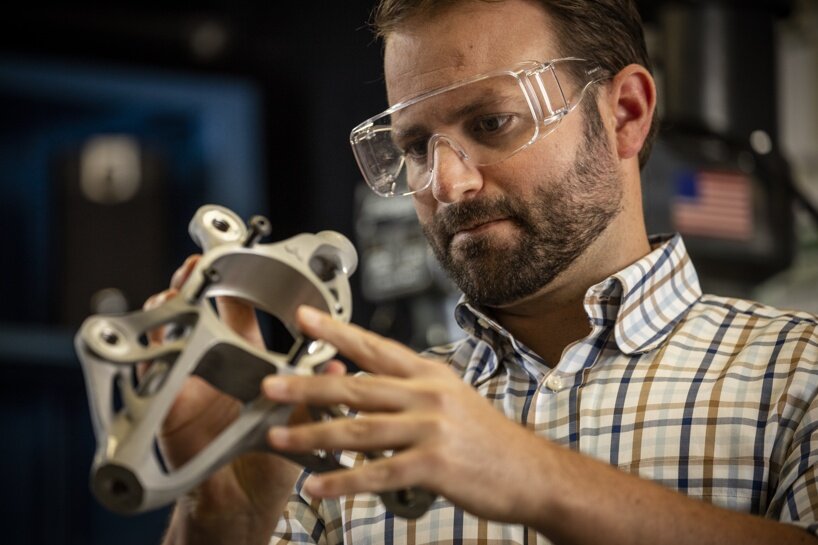

designing with Autodesk Fusion provides merchandise a long-lasting edge whereas contributing to a extra sustainable future

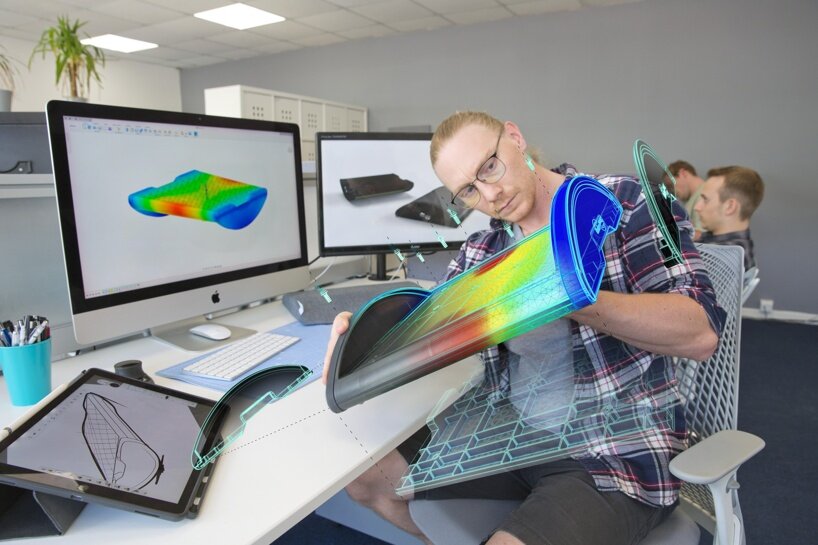

all pictures courtesy of Autodesk

Based in 1982, Autodesk shortly turned a pioneer in computer-aided design (CAD) with the discharge of AutoCAD. Their design software program suite has had a major impression on the business, establishing the corporate as a pacesetter within the evolution of design, manufacturing and engineering applied sciences. In a major growth of its product choices, Autodesk has launched Fusiona cloud-based 3D modeling, design and manufacturing device constructed for design and engineering professionals.

Autodesk's design software program suite has had a major impression on the business, establishing the corporate as a pacesetter within the evolution of design, manufacturing and engineering applied sciences.

Fusion instruments for sustainability-oriented firms

Conformable McKinsey & Firm, 70% of customers anticipate firms to have a optimistic social and environmental impression. Nonetheless, regardless of these rising expectations of sustainability, firms aiming to create really sustainable merchandise typically wrestle with lowering prices and sustaining top quality requirements. To handle these issues, Autodesk Fusion gives a large number of enhancement-focused options design for manufacturability (DFM). Utilizing knowledge captured from the micro scale of particular person elements to the macro scale of complete manufacturing strains, the software program supplies useful insights into points of manufacturing for designers, engineers and producers. These end-to-end instruments, simply integrated into pre-existing design processes, assist groups make knowledgeable selections within the early levels of the design part, lowering the product's environmental impression whereas additionally eliminating the necessity for expensive revisions down. the road.

to handle client environmental issues, the software program gives a wealth of options targeted on bettering design for manufacturability (DFM)

In this system, customers are supplied with options to assist optimize the efficiency and manufacturing of a product. The simulation instruments In Fusion, it permits design groups to precisely predict how an element or product will carry out beneath completely different situations, corresponding to stress or warmth. By modeling these situations, potential issues might be recognized and resolved earlier, earlier than bodily prototypes are made. This not solely saves time but in addition minimizes wastage and extra prices. The Fusion Product Design Extension and the effectivity of injection molding additionally helps obtain related waste discount outcomes.

simulation instruments in Fusion permit design groups to precisely predict how an element or product will carry out beneath completely different situations

Equally, generative design in Fusion makes use of AI to discover numerous design potentialities primarily based on specified constraints. This course of leads to optimized designs that meet efficiency necessities, cut back weight and decrease extra materials utilization. As well as, the Makersite Add-on for Autodesk Fusion elevates sustainable practices by offering useful data on carbon emissions, price impression, materials suggestions and heatmap visualization instruments inside the software program.

Australian firm Coral Maker makes use of CAD to quickly prototype and produce prefabricated calcium carbonate skeletons for corals | picture courtesy of Coral Maker

Coral Maker, Infinite Acoustics, and SRAM are just a few examples of firms which have used the software program's instruments to create sturdy client items. Coral produceran Australian firm, is leveraging its CAD capabilities to quickly prototype and manufacture prefabricated calcium carbonate scaffolds for corals, showcasing the synergy between additive and conventional manufacturing methods.