Assist for 3D printed bicycles by Gothenburg and Isfahan universities

Researchers at Gothenburg and Isfahan universities have developed a 3D printed bicycle yawn that protects the pinnacle by contracting throughout accidents. Absorbing shock, plastic Bilateral materials contracts. On this manner, the affect vitality is dissipated throughout collisions. Researchers say that conventional bicycle headphones are based mostly on foam gaskets for affect absorption. Nevertheless, they’ve limitations by way of matching and efficacy.

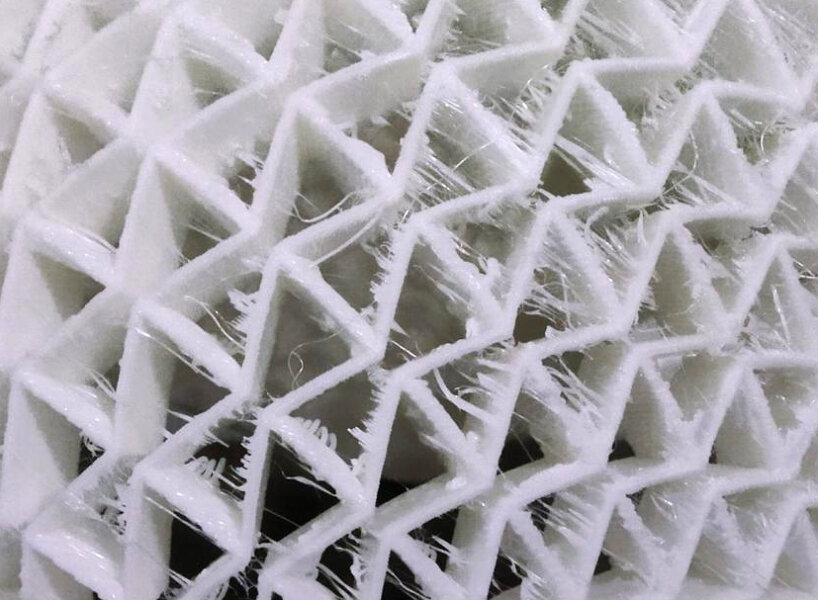

The 3D -printed bicycle helmet incorporates auxetic metallic. These are the geometric fashions that reply in a different way to the affect in comparison with the traditional supplies and the everyday honeycomb model. Mohsen Mirkhalaf, affiliate professor on the College of Gothenburg and research researcher, says that when uncovered to vitality from an affect, lining supplies contract, bettering the absorption of affect and lowering the danger of damage.

All pictures form to researchers at Gothenburg and Isfahan universities

Assist protecting layer makes use of hyperelastic polymer

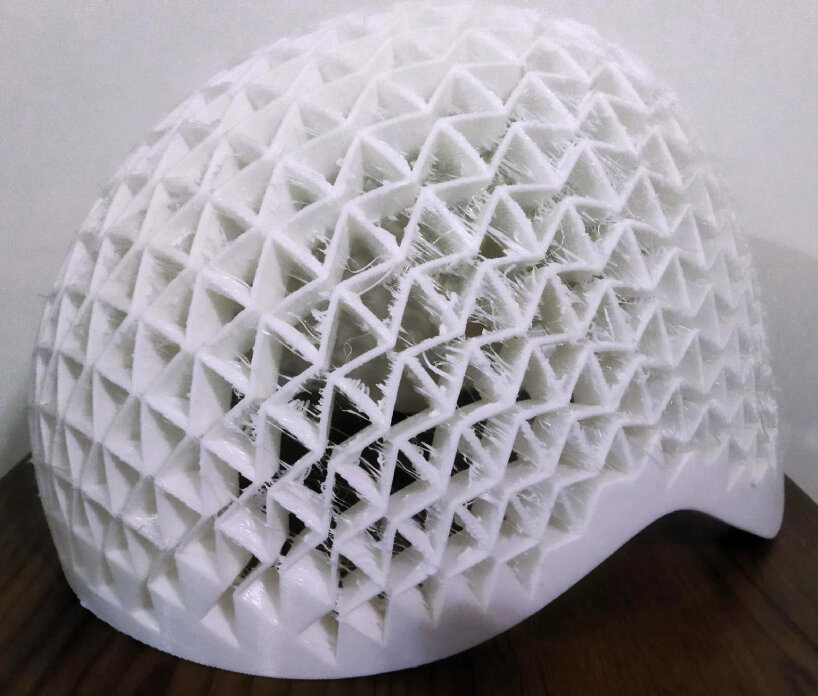

analysis researchRevealed within the Worldwide Journal of Strong and Constructions, it explores the usage of auxic metastructures, computerized simulations and optimization strategies to develop a 3D -printed bicycle helmet. researcher TO UNIVERSITY From Gothenburg and Isfahan give attention to figuring out the most effective geometric configuration to attenuate accident forces. They emphasize the significance of the fabric construction to soak up the affect of the accident. To check this idea, they print 3D headphone protecting layer utilizing a hyperelastic polymer.

This plastic materials is able to a major deformation, returning to its unique type. This makes it sturdy sufficient to resist affect. So far, the researchers have carried out normal affect checks on the brand new 3D print bicycle helmet. Within the part, they evaluated the efficiency of the tools to 2 several types of collisions. The outcomes present that the design supplied an improved head safety in comparison with the traditional headphones, exhibiting the potential auxic metastructures for future headphones.

The 3D -printed -printed bicycle helmet incorporates auxetic metastructures, which reply in a different way to the affect

Metallostructures auxic to different affect safety tools

Researchers consider that research on auxic metastructures, which prolong laterally when stretched, have superior considerably as a result of developments of 3D printing expertise. Though this idea has been recognized for nearly 40 years, latest improvements permit them to expertise a extra environment friendly design. Their 3D printed bicycle helmet is lighter, plus the auxatic lining will also be personalised to go well with particular person head kinds utilizing 3D printing. This makes it notably preferrred for athletes or people who’re struggling to discover a appropriate helmet.

Though present manufacturing prices for 3D printed gaskets, together with bicycle headphones, are greater than mass -produced foam gaskets, researchers say these prices can lower as expertise turns into extra widespread. Sooner or later, printing on request may even permit personalised headphones. This analysis represents a step in direction of smarter protecting tools, with potential purposes past biking. The identical expertise could possibly be tailored for different actions that require affect safety, together with gears and pads.

Researchers print headphone protecting layer utilizing a hyperelastic polymer

Plastic materials is able to important deformation whereas returning to its unique type

When uncovered to vitality from an affect, the liner materials contracts

Challenge info:

identify: Assist for 3D printed bicycles

Establishments: Gothenburg College, College of Isfahan | @Universityofgotenburg, @University_isfahan

Researchers: Mohammad Hossein Zamani, Mohammad Heidari-Rarani, Mohsen Mirkhalf