Biodegradable or plastic packaging made fully of cheese

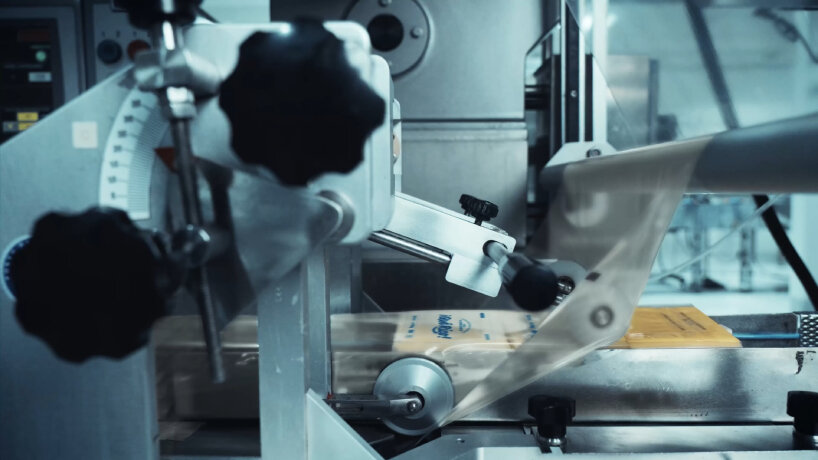

Ogilvy Colombia develops a prototype of Biodegradable PACKAGING or plastic manufactured from whey and cheese waste that breaks down in 300 days. The undertaking is known as self-embalmed cheese, as a result of the cheese is bioplastic from supplies taken and recycled from the manufacturing course of. The design groups, which incorporates Ogilvy Colombia and Nestlé, use microorganisms managed in a laboratory to supply PHA, or polyhydroxialnkanate, which is a kind of bioplastic. It then mixes it with natural aspect merchandise from cheese manufacturing, particularly whey or water -like fluid after cheese manufacture. The mix of those creates small pellets.

All the pictures kindly by Ogilvy Colombia

Materials that may break down in 300 days

These small pellets are then processed with injected air. This creates a skinny movie, much like the plastic, the biodegradable packaging for self-embarrassed cheese. design Groups say the prototype might help cut back waste and use conventional plastic. They add that the everyday plastic decomposes after about 900 years. With their biodegradable cheese packaging, the plastic could be damaged down from 300 days. As for the design, the movie is translucent and simple, though it has a smoked look, given the whey.

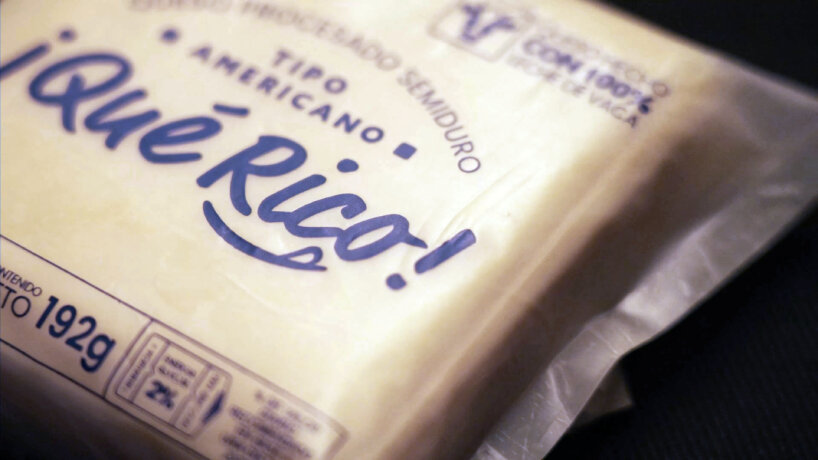

The corporate can nonetheless print over the cheese plastic, suggesting the robustness of the biodegradable packaging. The fabric is a possible mannequin for round packaging. It refers to packaging that may be reused, reconstituted or damaged down, reasonably than finish as waste. The biodegradable or plastic packaging, on this case, really comes from the cheese itself and finally returns to the surroundings, with out absolutely polluting it. The undertaking additionally offers for different potential makes use of of the duvet. On this case, corporations can undertake the fabric for various merchandise and functions, contributing to lowering the usage of plastic.

Cheese is wrapped with bioplastic from supplies taken over and recycled from manufacturing processes

Design groups use managed microorganisms in a laboratory to supply bioplastic

The coating can break down from 300 days

The whey of cheese makes up the recycled supplies of the shell

The detailed view of the packaging

The corporate can nonetheless print over plastic